Journal Description

Fuels

Fuels

is an international, peer-reviewed, open access journal on fuel science, published quarterly online by MDPI. The Institute of Energy and Fuel Processing Technology (ITPE) is affiliated to Fuels and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within ESCI (Web of Science), EBSCO, Ei Compendex, and other databases.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 25 days after submission; acceptance to publication is undertaken in 7.8 days (median values for papers published in this journal in the second half of 2024).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

Impact Factor:

2.7 (2023);

5-Year Impact Factor:

2.6 (2023)

Latest Articles

Pressurised Fuel Vessel Mass Estimation for High-Altitude PEM Unmanned Aircraft Systems

Fuels 2025, 6(2), 26; https://doi.org/10.3390/fuels6020026 - 3 Apr 2025

Abstract

The power to weight ratio of power plants is an important consideration, especially in the design of Unmanned Aircraft System (UAS). In this paper, a UAS with an MTOW of 35.3 kg, equipped with a fuel cell as a prime power supply to

[...] Read more.

The power to weight ratio of power plants is an important consideration, especially in the design of Unmanned Aircraft System (UAS). In this paper, a UAS with an MTOW of 35.3 kg, equipped with a fuel cell as a prime power supply to provide electrical power to the propulsion system, is considered. A pressure vessel design that can estimate and determine the total size and weight of the combined power plant of a fuel cell stack with hydrogen and air/oxygen vessels and the propulsion system of the UAS for high-altitude operation is proposed. Two scenarios are adopted to determine the size and weight of the pressure vessels required to supply oxygen to the fuel cell stack. Different types of stainless-steel materials are used in the design of the pressure vessel in order to find an appropriate material that provides low size and weight advantages. Also, the design of a hydrogen pressure vessel and mass estimation are also considered. The estimated sizes and weights of the hydrogen and oxygen vessels of the power plant and propulsion system in this research offer a maximum of four hours of flying time for the UAS mission; this is based on a Horizon (H-1000) Proton Exchange Membrane (PEM) stack.

Full article

(This article belongs to the Special Issue Advances in Propulsion and Energy Systems Utilising Alternative Fuels: Fuel Injection and Combustion Systems)

►

Show Figures

Open AccessArticle

Numerical Analysis on Impact of Membrane Thickness and Temperature on Characteristics of Biogas Dry Reforming Membrane Reactor Using Pd/Cu Membrane and Ni/Cr Catalyst

by

Akira Nishimura, Ryoma Ichii, Souta Yamada, Mizuki Ichikawa, Taisei Hayakawa and Eric Hu

Fuels 2025, 6(2), 25; https://doi.org/10.3390/fuels6020025 - 3 Apr 2025

Abstract

The purpose of this study is to reveal the characteristics of a Pd/Cu membrane and Ni/Cr catalyst adopted in a biogas dry reforming (BDR) membrane reactor by the numerical simulation procedure. The commercial software COMSOL Multiphysics ver. 6.2 was adopted in the numerical

[...] Read more.

The purpose of this study is to reveal the characteristics of a Pd/Cu membrane and Ni/Cr catalyst adopted in a biogas dry reforming (BDR) membrane reactor by the numerical simulation procedure. The commercial software COMSOL Multiphysics ver. 6.2 was adopted in the numerical simulation. COMSOL is one type of commercial software that can solve multiphysics phenomena, i.e., chemical reaction, fluid dynamics, heat transfer, etc. The impact of the initial reaction temperature and the thickness of the Pd/Cu membrane on the performance of the BDR membrane reactor using an Ni/Cr catalyst is also investigated. The initial reaction temperatures adopted were 400 °C, 500 °C, and 600 °C, and the thicknesses of the Pd/Cu membrane were varied at 20 μm, 40 μm, and 60 μm. It was discovered that when the initial reaction temperature was raised, the molar concentration of H2 increased while the molar concentrations of CH4 and CO2 decreased. Because the penetration resistance of the Pd/Cu membrane decreased with the decrease in the thickness of the Pd/Cu membrane, the molar concentrations of H2 remaining in the Pd/Cu membrane and sweep chamber rose with the decrease in the thickness of the Pd/Cu membrane.

Full article

(This article belongs to the Special Issue Waste to Fuels and Chemicals: Toward a Clean, Green, and Sustainable World)

►▼

Show Figures

Figure 1

Open AccessReview

Minireview: Intensified Low-Temperature Fischer–Tropsch Reactors for Sustainable Fuel Production

by

Yadolah Ganjkhanlou, Evert Boymans and Berend Vreugdenhil

Fuels 2025, 6(2), 24; https://doi.org/10.3390/fuels6020024 - 1 Apr 2025

Abstract

►▼

Show Figures

Low-temperature Fischer–Tropsch (LTFT) synthesis converts syngas to diesel/wax at 200–250 °C. The LTFT reaction has recently received renewed interest, as it can be used for converting syngas from renewable sources (biomass and waste) to high-value fuels and chemicals. Conventional LTFT reactors, such as

[...] Read more.

Low-temperature Fischer–Tropsch (LTFT) synthesis converts syngas to diesel/wax at 200–250 °C. The LTFT reaction has recently received renewed interest, as it can be used for converting syngas from renewable sources (biomass and waste) to high-value fuels and chemicals. Conventional LTFT reactors, such as fixed-bed and slurry reactors, are not entirely suitable for bio-syngas conversion due to their smaller scale compared to fossil fuel-based syngas processes. This review explores advancements in intensifying LTFT reactors suitable for bio-syngas conversion, enabling smaller scale and dynamic operation. Various strategies for enhancing heat and mass transfer are discussed, including the use of microchannel reactors, structured reactors, and other designs where either one or both the heat and mass transfer are intensified. These technologies offer improved performance and economics for small LTFT units by allowing flexible operation, with increased syngas conversion and reduced risk of overheating. Additionally, this review presents our outlook and perspectives on strategies for future intensification.

Full article

Figure 1

Open AccessArticle

Enhancing Bioenergy Production from Chlorella via Salt-Induced Stress and Heat Pretreatment

by

Themistoklis Sfetsas, Sopio Ghoghoberidze, Petros Samaras, Polycarpos Falaras and Thomas Kotsopoulos

Fuels 2025, 6(2), 23; https://doi.org/10.3390/fuels6020023 - 27 Mar 2025

Abstract

This study presents an integrated strategy to optimize biofuel production from Chlorella sorokiniana (CSO) and Chlorella vulgaris (CVU) by combining salt-induced stress and thermal pretreatment. The microalgae were cultivated in anaerobic digestate effluent (ADE) under stress and non-stress conditions to evaluate nutrient availability’s

[...] Read more.

This study presents an integrated strategy to optimize biofuel production from Chlorella sorokiniana (CSO) and Chlorella vulgaris (CVU) by combining salt-induced stress and thermal pretreatment. The microalgae were cultivated in anaerobic digestate effluent (ADE) under stress and non-stress conditions to evaluate nutrient availability’s impact on biomass composition. Salt stress significantly enhanced lipid accumulation, with CVU exhibiting a 51.6% increase. Thermal pretreatment of biomass at 90 °C for 10 h achieved the highest methane yield (481 mL CH4/g VS), with CVU outperforming CSO. Milder pretreatment conditions (40 °C for 4 h) were more energy-efficient for CSO, achieving a yield of 2.67%. Fatty acid profiles demonstrated species-specific biodiesel properties, with CSO rich in oleic acid (33.47%) offering enhanced oxidative stability and cold flow performance, while CVU showed a higher polyunsaturated fatty acid content. This research highlights the economic viability of using ADE as a low-cost cultivation medium and the potential for scalable thermal pretreatments. Future research should focus on reducing energy demands of pretreatment processes and exploring alternative stress induction methods to further enhance biofuel yields. These findings offer valuable insights for tailoring cultivation and processing strategies to maximize lipid and methane production, supporting sustainable and economically viable dual biofuel production systems.

Full article

(This article belongs to the Special Issue Combining Waste Treatment with Biofuels/Bioenergy Production)

►▼

Show Figures

Figure 1

Open AccessArticle

Laboratory Modeling of the Bazhenov Formation Organic Matter Transformation in a Semi-Open System: A Comparison of Oil Generation Kinetics in Two Samples with Type II Kerogen

by

Anton G. Kalmykov, Valentina V. Levkina, Margarita S. Tikhonova, Grigorii G. Savostin, Mariia L. Makhnutina, Olesya N. Vidishcheva, Dmitrii S. Volkov, Andrey V. Pirogov, Mikhail A. Proskurnin and Georgii A. Kalmykov

Fuels 2025, 6(2), 22; https://doi.org/10.3390/fuels6020022 - 25 Mar 2025

Abstract

►▼

Show Figures

In this study, Kerogen conversion and oil production laboratory modeling results in Bazhenov formation source rock samples (Western Siberia, Russia) are presented. Two samples from one well with a similar composition and immature type II kerogen, which were accumulated in the same deep-sea

[...] Read more.

In this study, Kerogen conversion and oil production laboratory modeling results in Bazhenov formation source rock samples (Western Siberia, Russia) are presented. Two samples from one well with a similar composition and immature type II kerogen, which were accumulated in the same deep-sea conditions, were used for this investigation. Hydrous pyrolysis was performed under 300 °C, with liquid products and a sample portion collected every 12 h to study kerogen parameters via pyrolysis and the synthetic-oil composition via GC–MS. The transformation of pyrolytic parameters was similar to the natural trend previously determined for Bazhenov source rocks with different maturities. The synthetic oils’ normal alkane composition and biomarker parameters transformed with time. Sedimentary conditions and lithology biomarker parameters presumed to be constant (Pr/Ph, Ph/C18, H29/H30, and DBT/Phen) changed depending on the heating duration. The oil maturation increased slightly. Differences between the samples were detected in hydrocarbon generation endurance (5 and 8 days), n-alkane composition, and C27/C29 and DBT/Phen. A hypothesis about the influence of kerogen variability and mineral matrix on oil production was made. This paper provides the basis for more detailed and accurate investigation of the factors affecting kerogen cracking and hydrocarbon formation.

Full article

Figure 1

Open AccessArticle

Optimizing Methanol Flow Rate for Enhanced Semi-Passive Mini-Direct Methanol Fuel Cell Performance

by

Laura Faria and Vicenta María Barragán

Fuels 2025, 6(2), 21; https://doi.org/10.3390/fuels6020021 - 24 Mar 2025

Abstract

►▼

Show Figures

Direct methanol fuel cells (DMFCs) typically operate in passive mode, where methanol is distributed across the membrane electrode assembly through natural diffusion. Usual methanol concentrations range from 1% to 5% by weight (wt.%), although this can vary depending on the specific configuration and

[...] Read more.

Direct methanol fuel cells (DMFCs) typically operate in passive mode, where methanol is distributed across the membrane electrode assembly through natural diffusion. Usual methanol concentrations range from 1% to 5% by weight (wt.%), although this can vary depending on the specific configuration and application. In this work, the effect of an additional pumping system to supply the methanol has been analyzed by varying the methanol flow rate within the pump’s range. To this end, a parametric experimental study was carried out to study the influence of temperature (25–40 °C), concentration (0.15–6 wt.% methanol in water), and the flow rate of methanol (1.12–8.65 g/s) on the performance of a single mini-direct methanol fuel cell (DMFC) operating in semi-passive mode with a passive cathode and an active anode. Open circuit voltage, maximum power density, and cell efficiency were analyzed. To this purpose, open circuit voltage and current–voltage curves were measured in different experimental conditions. Results indicate that temperature is the most decisive parameter to increase DMFC performance. For all methanol concentrations and flow rates, performance improves with higher operating temperatures. However, the impact of the concentration and flow rate depends on the other parameters. The operating optimal concentration was 1% wt. At this concentration, a maximum power of 14.2 mW was achieved at 40 °C with a methanol flow of 7.6 g/s. Under these same conditions, the cell also reached its maximum efficiency of 23%. The results show that switching from passive to semi-passive mode generally increases open-circuit voltage and maximum power, thus improving fuel cell performance, likely due to the enhanced uniform distribution of the reactant in semi-passive mode. However, further increases in flow rate led to a decrease in performance, probably due to the methanol crossover effect. An optimal methanol flow rate is observed, depending on methanol flow temperature and concentration.

Full article

Figure 1

Open AccessArticle

Flow Field Analysis of a Hydrogen-Fueled Flame Holder Using Particle Image Velocimetry (PIV)

by

Florin Gabriel Florean, Andreea Mangra, Marius Enache, Razvan Carlanescu and Cristian Carlanescu

Fuels 2025, 6(1), 20; https://doi.org/10.3390/fuels6010020 - 7 Mar 2025

Abstract

►▼

Show Figures

The stability of hydrogen-fueled flames in afterburner systems is crucial for advancing clean energy technologies but is challenged by intense turbulence and flow variability. This study uniquely integrates advanced particle image velocimetry (PIV) techniques to investigate the flow dynamics around a V-gutter flame

[...] Read more.

The stability of hydrogen-fueled flames in afterburner systems is crucial for advancing clean energy technologies but is challenged by intense turbulence and flow variability. This study uniquely integrates advanced particle image velocimetry (PIV) techniques to investigate the flow dynamics around a V-gutter flame holder fueled with 100% hydrogen. Detailed velocity measurements were conducted to analyze the standard deviation of Vy, average Vy, average V, and uncertainty of Vy, as well as the mean swirling strength and mean vorticity profiles across multiple horizontal and vertical lines. The results reveal significant flow variability and turbulence intensity near the flame holder, with standard deviation peaks of up to 12 m/s, indicating zones of high turbulence and potential flame instability. The mean swirling strength, peaking at 850,000 [1/s2], and vorticity values up to 5000 [1/s] highlight intense rotational motion, enhancing fuel–air mixing and flame stabilization. The average Vy remained stable near the centerline, ensuring balanced flow conditions, while lateral deviations of up to −10 m/s reflect vortical structures induced by the flame holder geometry. Low uncertainty values, typically below 1 m/s, validate the precision of the PIV measurements, ensuring a reliable representation of the flow field. By providing a detailed analysis of turbulence structures and their impact on hydrogen combustion, this study offers novel insights into the interplay between flow dynamics and flame stability. These findings not only advance the understanding of hydrogen-fueled afterburner systems but also demonstrate the critical role of rotational flow structures in achieving stable and efficient combustion. By addressing key challenges in hydrogen combustion, this study provides a foundation for designing more robust and environmentally sustainable combustion systems, contributing to the transition toward clean energy technologies.

Full article

Figure 1

Open AccessArticle

Off-Design Analysis of Power-to-Gas System Based on Solid-Oxide Electrolysis with Nominal Power of 25 kW

by

Grzegorz Koziński, Jarosław Milewski and Jakub Kupecki

Fuels 2025, 6(1), 19; https://doi.org/10.3390/fuels6010019 - 6 Mar 2025

Abstract

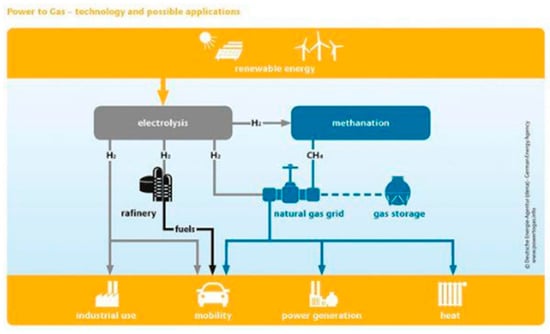

The deployment of large installed power capacities from intermittent renewable energy sources requires balancing to ensure the steady and safe operation of the electrical grid. New methods of energy storage are essential to store excess electrical power when energy is not needed and

[...] Read more.

The deployment of large installed power capacities from intermittent renewable energy sources requires balancing to ensure the steady and safe operation of the electrical grid. New methods of energy storage are essential to store excess electrical power when energy is not needed and later use it during high-demand periods, both in the short and long term. Power-to-Gas (P2G) is an energy storage solution that uses electric power produced from renewables to generate gas fuels, such as hydrogen, which can be stored for later use. Hydrogen produced in this manner can be utilized in energy storage systems and in transportation as fuel for cars, trams, trains, or buses. Currently, most hydrogen is produced from fossil fuels. Solid-oxide electrolysis (SOE) offers a method to produce clean hydrogen without harmful emissions, being the most efficient of all electrolysis methods. The objective of this work is to determine the optimal operational parameters of an SOE system, such as lower heating value (LHV)-based efficiency and total input power, based on calculations from a mathematical model. The results are provided for three different operating temperature levels and four different steam utilization ratios. The introductory chapter outlines the motivation and background of this work. The second chapter explains the basics of electrolysis and describes its different types. The third chapter focuses on solid-oxide electrolysis and electrolyzer systems. The fourth chapter details the methodology, including the mathematical formulations and software used for simulations. The fifth chapter presents the results of the calculations with conclusions. The final chapter summarizes this work.

Full article

(This article belongs to the Special Issue Sustainability Assessment of Renewable Fuels Production)

►▼

Show Figures

Figure 1

Open AccessArticle

Impact of Membrane Thickness on Characteristics of Biogas Dry Reforming Membrane Reactor Using Pd/Cu Membrane and Ni/Cr/Ru Catalyst

by

Akira Nishimura, Mizuki Ichikawa, Taisei Hayakawa, Souta Yamada, Ryoma Ichii and Mohan Lal Kolhe

Fuels 2025, 6(1), 18; https://doi.org/10.3390/fuels6010018 - 3 Mar 2025

Abstract

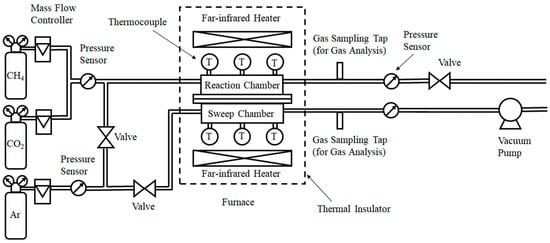

The aim of the present study was to clarify the influence of the thickness of the Pd/Cu membrane on the characteristics of biogas dry reforming (BDR) with aNi/Cr/Ru catalyst. We also clarified the impact of the reaction temperature, the molar ratio of CH

[...] Read more.

The aim of the present study was to clarify the influence of the thickness of the Pd/Cu membrane on the characteristics of biogas dry reforming (BDR) with aNi/Cr/Ru catalyst. We also clarified the impact of the reaction temperature, the molar ratio of CH4:CO2, the differential pressure between the reaction and sweep chambers, and the introduction of a sweep gas on the characteristics of a BDR reactor with a Pd/Cu membrane and a Ni/Cr/Ru catalyst. Through this study’s results, we clarify that the concentration of H2 in the reaction chamber and the sweep chamber increases with the increase in the reaction temperature. In addition, this study clarifies that the highest concentration of H2 in the reaction chamber and the sweep chamber can be obtained with a molar ratio of CH4:CO2 = 1.5:1. This study also clarifies that the highest concentration of H2 can be obtained with a thickness of 40 μm, a molar ratio of CH4:CO2 = 1.5:1, and a differential pressure between the reaction chamber and the sweep chamber of 0 MPa without a sweep gas, which was 4890 ppmV in the reaction chamber and 38 ppmV in the sweep chamber. Under these conditions, CH4 conversion, H2 yield, and thermal efficiency were 75.0%, 0.214%, and 2.92%, respectively.

Full article

(This article belongs to the Special Issue Biofuels and Bioenergy: New Advances and Challenges)

►▼

Show Figures

Figure 1

Open AccessArticle

Research on the Efficiency of Solid Biomass Fuels and Consumer Preferences in Bulgaria

by

Penka Zlateva, Angel Terziev, Mariana Murzova and Nevena Milcheva Mileva

Fuels 2025, 6(1), 17; https://doi.org/10.3390/fuels6010017 - 3 Mar 2025

Abstract

This study examines the qualities and potential uses of various types of biomass as fuel, focusing on wood pellets, sunflower husk pellets and mixed pellets. The primary objective is to analyze the thermal and energy properties of these pellets in order to evaluate

[...] Read more.

This study examines the qualities and potential uses of various types of biomass as fuel, focusing on wood pellets, sunflower husk pellets and mixed pellets. The primary objective is to analyze the thermal and energy properties of these pellets in order to evaluate their efficiency and acceptance by consumers in the Bulgarian market. Thermogravimetric analysis (TG) and differential scanning calorimetry (DSC) are employed, revealing that the processes of drying and volatile substance release are accompanied by energy absorption, with combustion being the main stage where most heat is generated. The results show that wood pellets have 7.31% moisture, 0.72% ash and a calorific value of 18.33 kJ/kg; sunflower husk pellets have 7.62% moisture, 2.42% ash and a calorific value of 19.63 kJ/kg; and mixed pellets have 7.07% moisture, 0.69% ash and a calorific value of 18.05 kJ/kg. These findings indicate that the pellets achieve efficient combustion with minimal mass loss. The conducted marketing research reveals that Bulgarian consumers prefer wood and mixed pellets for their efficiency, although sunflower husk pellets are more affordable. Key factors influencing consumer choice include price, which is important for 51% of the respondents, and quality, prioritized by 34%. The conclusion of this study is that pellets are a promising energy source with good environmental and economic characteristics, and the results can contribute to the development of more efficient fuels adapted to the needs of the market and consumers.

Full article

(This article belongs to the Special Issue Biofuels and Bioenergy: New Advances and Challenges)

►▼

Show Figures

Figure 1

Open AccessArticle

Methane–Natural Clay Interfacial Interactions as Revealed by High-Pressure Magic Angle Spinning (MAS) Nuclear Magnetic Resonance (NMR) Spectroscopy

by

Salim Ok, Julia M. Sheets, Susan A. Welch and David R. Cole

Fuels 2025, 6(1), 16; https://doi.org/10.3390/fuels6010016 - 18 Feb 2025

Abstract

►▼

Show Figures

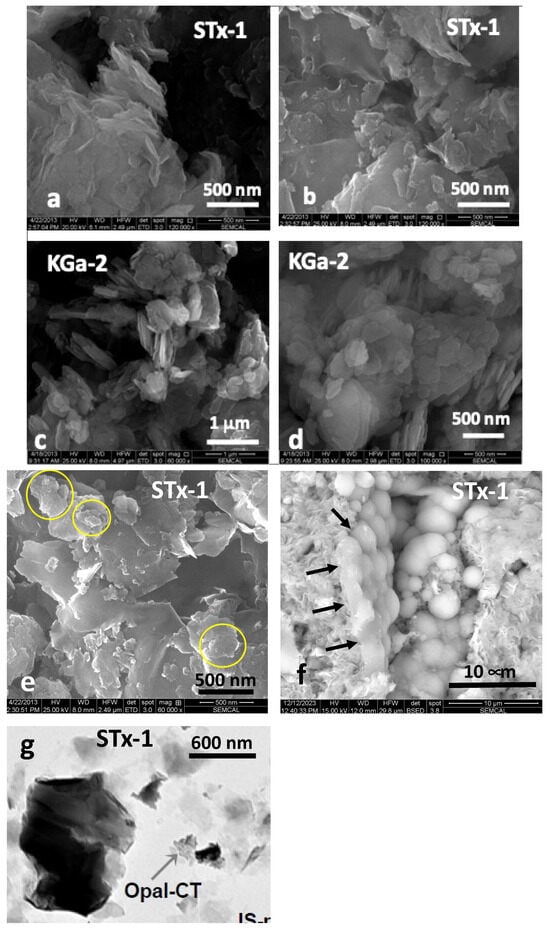

The current investigation aims to offer fundamental, molecular- to microscopic-level descriptions of methane gas inside natural source clay minerals. Texas montmorillonite (STx-1), Georgia kaolinite (KGa-2), and Ca2+-saturated Texas montmorillonite (Ca-STx-1, Ca-bentonite) were utilized as subsurface model clay minerals for elucidating nano-confinement

[...] Read more.

The current investigation aims to offer fundamental, molecular- to microscopic-level descriptions of methane gas inside natural source clay minerals. Texas montmorillonite (STx-1), Georgia kaolinite (KGa-2), and Ca2+-saturated Texas montmorillonite (Ca-STx-1, Ca-bentonite) were utilized as subsurface model clay minerals for elucidating nano-confinement behaviors of 13C-labeled methane gas. High-pressure magic angle spinning (MAS) nuclear magnetic resonance (NMR) was used to describe the interactions between methane and the clays by varying temperature and pressure. Proton-decoupled 13C-NMR spectra were acquired at 28.2 bar at 307 K, 32.6 bar at 346 K, 56.4 bar at 307 K, 65.1 bar at 346 K, 112.7 bar at 307 K, and 130.3 bar at 346 K. In the pure state, no significant thermal effect on the behavior of methane was observed. However, there was a perceptible variation in the chemical shift position of confined methane in the mixtures with the clays up to 346 K. Conversely, the 13C-NMR chemical shift of methane altered by varying pressure in a pure state, and the mixtures with clays, attributed to the interaction of methane with the clay surfaces or the nanopore network of the clay–silica mixed phase. Pressure-induced shifts in methane peak positions were observed: 0.25 ppm (28.2–56.4 bar) and 0.47 ppm (56.4–112.3 bar) at 307 K. For methane in a montmorillonite mixture, shifts were 0.32 ppm for bulk-like methane and 0.20 ppm for confined methane under similar conditions. At 346 K, increasing pressure from 65.1 to 130.3 bar caused shifts exceeding 0.50 ppm, with bulk-like methane showing a 0.64 ppm shift and confined methane a 0.57 ppm shift. There was only one 13C-NMR methane peak in the mixture with either kaolinite (KGa-2) or Ca-bentonite with line broadening compared to that of pure methane. Still, two peaks were observed in the mixture with STx-1, explained by the imbibition and mobility of methane in the pore network.

Full article

Figure 1

Open AccessArticle

Development and Characterization of κ-Carrageenan and Boron Nitride Nanoparticle Membranes for Improved Ionic Conductivity in Fuel Cells

by

Ermides Chavez-Baldovino, Carlos A. Malca-Reyes, Roberto Masso, Peter Feng and Liz M. Díaz-Vázquez

Fuels 2025, 6(1), 15; https://doi.org/10.3390/fuels6010015 - 12 Feb 2025

Abstract

►▼

Show Figures

The development of alga-based biodegradable membranes represents a significant advancement in fuel cell technology, aligning with the need for sustainable material solutions. In a significant advancement for sustainable energy technologies, we have developed a novel biodegradable κ-carrageenan (KC) and boron nitride (BN) nanoparticle

[...] Read more.

The development of alga-based biodegradable membranes represents a significant advancement in fuel cell technology, aligning with the need for sustainable material solutions. In a significant advancement for sustainable energy technologies, we have developed a novel biodegradable κ-carrageenan (KC) and boron nitride (BN) nanoparticle membrane, optimized with ammonium sulfate (NHS). This study employed a set of characterization techniques, including thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC), where thermal anomalies were observed in the membranes around 160 °C and 300 °C as products of chemical decomposition. X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) revealed the phases corresponding to the different precursors, whose value in the EDS measurements reached a maximum in the KC/BN/NHS5% membrane at 2.31 keV. In terms of the mechanical properties (MPs), a maximum tensile stress value of 10.96 MPa was achieved for the KC/BN sample. Using Fourier transform infrared spectroscopy (FTIR), the physicochemical properties of the membranes were evaluated. Our findings reveal that the KC/BN/NHS1% membrane achieves an exceptional ionic conductivity of 7.82 × 10−5 S/cm, as determined by impedance spectroscopy (IS). The properties of the developed membrane composite suggest possible broader applications in areas such as sensor technology, water purification, and ecologically responsive packaging. This underscores the role of nanotechnology in enhancing the functional versatility and sustainability of energy materials, propelling the development of green technology solutions.

Full article

Figure 1

Open AccessReview

Microbial Electrolysis Cells for H2 Generation by Treating Acid Mine Drainage: Recent Advances and Emerging Trends

by

Wenwen Cui and Shunde Yin

Fuels 2025, 6(1), 14; https://doi.org/10.3390/fuels6010014 - 12 Feb 2025

Abstract

Microbial electrolysis cells (MECs) are receiving increasing scholarly recognition for their capacity to simultaneously remediate contaminated streams and generate renewable hydrogen. Within the realm of acid mine drainage (AMD) treatment, MECs demonstrate pronounced advantages by merging pollutant mitigation with hydrogen production, thereby attracting

[...] Read more.

Microbial electrolysis cells (MECs) are receiving increasing scholarly recognition for their capacity to simultaneously remediate contaminated streams and generate renewable hydrogen. Within the realm of acid mine drainage (AMD) treatment, MECs demonstrate pronounced advantages by merging pollutant mitigation with hydrogen production, thereby attracting intensified research interest. Drawing on 1321 pertinent publications extracted from the Web of Science Core Collection (2004–2024), this bibliometric assessment systematically elucidates the current research landscape and prospective directions in MEC-based AMD remediation and H2 synthesis. Key thematic areas encompass (1) a detailed appraisal of distinctive publication dynamics within this specialized domain; (2) insights into the principal contributing nations, institutions, journals, and academic fields; and (3) a synthesized overview of technological milestones, emerging investigative foci, and prospective developmental pathways. By critically reviewing extant knowledge, this evaluation offers meaningful guidance to researchers newly engaging with MEC-driven AMD treatment while illuminating the technological trajectories poised to shape the future of this evolving field.

Full article

(This article belongs to the Special Issue Clean and Renewable Hydrogen Fuel)

►▼

Show Figures

Figure 1

Open AccessArticle

Natural and Waste Materials for Desulfurization of Gaseous Fuels and Petroleum Products

by

Iliya Iliev, Antonina Filimonova, Andrey Chichirov, Alena Vlasova, Ruzina Kamalieva and Ivan Beloev

Fuels 2025, 6(1), 13; https://doi.org/10.3390/fuels6010013 - 7 Feb 2025

Abstract

►▼

Show Figures

Currently, the key challenge of the oil-refining industry worldwide is to produce environmentally friendly fuel in large volumes to meet market demand, which is due to strict environmental standards governing the permissible sulfur content in fuel. Natural gas, refinery gas, and coal gas

[...] Read more.

Currently, the key challenge of the oil-refining industry worldwide is to produce environmentally friendly fuel in large volumes to meet market demand, which is due to strict environmental standards governing the permissible sulfur content in fuel. Natural gas, refinery gas, and coal gas contain acid gases such as hydrogen sulfide and carbon dioxide. These compounds must be removed from the gas stream because of the toxicity of H2S and to prevent the acid gas-induced corrosion of pipelines and facilities. Hydrogen sulfide is released as a result of various industrial processes, and its removal is critical because this compound can cause corrosion and environmental damage even at low concentrations. Sulfur compounds are also present in natural gas, biofuels and other fuel gases used in power plants. This article proposes new adsorbents of natural and waste origin and presents the results of their testing for the removal of acid gases. This paper also considers methods for the preparation of adsorbents from waste and procedures for the removal of sulfur-containing compounds. Using agricultural, industrial waste to produce activated sorbents not only solves the problem of waste disposal but also reduces the cost of desulfurization, contributing to the creation of sustainable and environmentally friendly technologies. The Review Section comprehensively summarizes current research on hydrogen sulfide removal in gas cleaning processes using agricultural and industrial waste as highly efficient adsorbents. In the Experimental Section, 10 composite materials based on natural raw materials and wastes, as well as 6 commercial adsorbents, were synthesized and tested under laboratory conditions. The choice of materials for the adsorbent production was based on the principles of environmental friendliness, availability, and cost-effectiveness. The developed materials based on modified sludge from water treatment plants of thermal power plants are effective sorbents for the purification of gas emissions from petrochemical enterprises. For industrial use, it is necessary to solve the problems of increasing the economic attractiveness of sorbents from waste, the ability of regeneration, the competitive adsorption of pollutants, the use of indicator sorbents, the optimization of operating conditions, and safe waste disposal.

Full article

Figure 1

Open AccessReview

Decarbonizing Insular Energy Systems: A Literature Review of Practical Strategies for Replacing Fossil Fuels with Renewable Energy Sources

by

Paul Arévalo, Danny Ochoa-Correa, Edisson Villa-Ávila, Juan L. Espinoza and Esteban Albornoz

Fuels 2025, 6(1), 12; https://doi.org/10.3390/fuels6010012 - 6 Feb 2025

Abstract

►▼

Show Figures

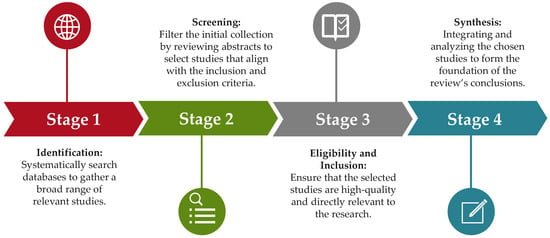

The reliance on fossil fuels for electricity production in insular regions creates critical environmental, economic, and logistical challenges, particularly for ecologically fragile islands. Transitioning to renewable energy is essential to mitigate these impacts, enhance energy security, and preserve unique ecosystems. This systematic review

[...] Read more.

The reliance on fossil fuels for electricity production in insular regions creates critical environmental, economic, and logistical challenges, particularly for ecologically fragile islands. Transitioning to renewable energy is essential to mitigate these impacts, enhance energy security, and preserve unique ecosystems. This systematic review addresses key research questions: what practical strategies have proven effective in reducing fossil fuel dependency in island contexts, and what barriers hinder their widespread adoption? By applying the PRISMA methodology, this study examines a decade (2014–2024) of research on renewable energy systems, highlighting successful initiatives such as the integration of solar and wind systems in Hawaii, energy storage advancements in La Graciosa, hybrid renewable grids in the Galápagos Islands, and others. Specific barriers include high upfront costs, regulatory challenges, and technical limitations, such as grid instability due to renewable energy intermittency. This review contributes by synthesizing lessons from diverse case studies and identifying innovative approaches like hydrogen storage, predictive control systems, and community-driven renewable projects. The findings offer actionable insights for policymakers and researchers to accelerate the transition towards sustainable energy systems in island environments.

Full article

Figure 1

Open AccessArticle

Geochemical and Thermodynamic Study of Formation Water for Reservoir Management in Bibi Hakimeh Oil and Gas Field, Iran

by

Seyed Hossein Hashemi, Amir Karimian Torghabeh, Abbas Niknam, Seyed Abdolrasoul Hashemi, Mohamad Hosein Mahmudy Gharaie and Nuno Pimentel

Fuels 2025, 6(1), 11; https://doi.org/10.3390/fuels6010011 - 5 Feb 2025

Abstract

►▼

Show Figures

This research evaluates the mineral ions and their concentrations in formation water from five well samples of the Bibi Hakimeh oil field (Iran). The analysis reveals the presence of calcium (Ca2+), sodium (Na+), and magnesium (Mg2+) cations,

[...] Read more.

This research evaluates the mineral ions and their concentrations in formation water from five well samples of the Bibi Hakimeh oil field (Iran). The analysis reveals the presence of calcium (Ca2+), sodium (Na+), and magnesium (Mg2+) cations, as well as sulfate (SO42−), bicarbonate (HCO3−), and chloride (Cl−) anions, which are soluble in water within the Bibi Hakimeh oil formation. Furthermore, mineral deposits of CaSO4, CaSO4.2H2O, CaCO3, and MgCO3 are investigated and predicted using StimCADE 2 software. The findings highlight the significant chemical precipitation of calcium sulfate and calcium carbonate mineral deposits under the operating conditions of the Bibi Hakimeh oil well. The geochemical composition of the formation waters is discussed to understand the equilibrium conditions and possible influence of the physical parameters. Additionally, this study examines the interaction between rock and water of the Bibi Hakimeh formation, revealing a notable correlation between the concentration of calcium and magnesium ions and the water–rock reaction in this field.

Full article

Figure 1

Open AccessArticle

Integrating Renewable Fuels and Sustainable Practices in Equestrian Centers: A Model for Carbon Footprint Reduction and Environmental Impact Mitigation

by

Matías Fernández-Cortés, Marta Revuelta-Aramburu and Carlos Morales-Polo

Fuels 2025, 6(1), 10; https://doi.org/10.3390/fuels6010010 - 4 Feb 2025

Abstract

►▼

Show Figures

This research investigates the feasibility of utilizing anaerobic digestion to produce biogas from organic waste generated at an equestrian center, emphasizing energy savings and environmental sustainability. The biogas system produces an estimated 85,495 kWh annually, surpassing the center’s electricity consumption of 18,644 kWh.

[...] Read more.

This research investigates the feasibility of utilizing anaerobic digestion to produce biogas from organic waste generated at an equestrian center, emphasizing energy savings and environmental sustainability. The biogas system produces an estimated 85,495 kWh annually, surpassing the center’s electricity consumption of 18,644 kWh. This reduces greenhouse gas emissions by 2753 kg of CO2. Photovoltaic systems, which meet 70.77% of the energy demand, further contribute to a reduction of 1178 kg of CO2. Substituting fossil fuels with biofuels and planting 1700 trees achieved reductions of 26,263 kg of CO2 and 51,033 kg of CO2, respectively, resulting in a 49% overall carbon footprint reduction. This study evaluates the economic viability of biogas systems in the equestrian sector and optimal feedstock characteristics for efficient production. Additionally, complementary strategies, including photovoltaic solar panels and water management systems, are analyzed for their roles in promoting sustainable resource management. These integrated solutions support a transition to a circular economy while reducing environmental impacts and fostering energy independence in the equestrian industry.

Full article

Figure 1

Open AccessArticle

Numerical and Experimental Investigation on Combustion Characteristics and Pollutant Emissions of Pulverized Coal and Biomass Co-Firing in a 500 kW Burner

by

Rachapat Chaiyo, Jakrapop Wongwiwat and Yanin Sukjai

Fuels 2025, 6(1), 9; https://doi.org/10.3390/fuels6010009 - 30 Jan 2025

Cited by 2

Abstract

►▼

Show Figures

The global shift towards clean energy has been driven by the need to address global warming, which is exacerbated by economic expansion and rising energy demands. Traditional fossil fuels, particularly coal, emit more pollutants than other fuels. Recent studies have shown significant efforts

[...] Read more.

The global shift towards clean energy has been driven by the need to address global warming, which is exacerbated by economic expansion and rising energy demands. Traditional fossil fuels, particularly coal, emit more pollutants than other fuels. Recent studies have shown significant efforts in using biomass as a replacement or co-firing it with coal. This is because biomass, being a solid fuel, has a combustion mechanism similar to that of coal. This study investigates the co-firing behavior of pulverized coal and biomass in a semi-combustion furnace with a 500 kW heat input, comprising a pre-chamber and a main combustion chamber. Using computational fluid dynamics (CFD) simulations with ANSYS Fluent 2020 R1, the study employs species transport models to predict combustion reactions and discrete phase models (DPM) to track fuel particle movement. These models are validated against experimental data to ensure accurate predictions of mixed fuel combustion. The research examines various biomass-to-coal ratios (0%, 25%, 50%, 75%, and 100%) to understand their impact on combustion temperature and emissions. Results show that increasing the biomass ratio reduces combustion temperature due to biomass’s lower heating value, higher moisture content, and larger particle size, leading to less efficient combustion and higher CO emissions. However, this temperature reduction also correlates with lower NOx emissions. Additionally, biomass’s lower nitrogen and sulfur content contributes to further reductions in NOx and SO2 emissions. Despite biomass having higher volatile matter content, which results in quicker combustion, coal demonstrates a higher carbon burnout rate, indicating more efficient carbon combustion. The study concludes that while pure coal combustion efficiency is higher at 87.7%, pure biomass achieves only 77.3% efficiency. Nonetheless, increasing biomass proportions positively impacts emissions, reducing harmful NOx and SO2 levels.

Full article

Figure 1

Open AccessReview

Systematic and Bibliometric Review of Biomethane Production from Biomass-Based Residues: Technologies, Economics and Environmental Impact

by

Gonçalo A. O. Tiago, Naresh P. B. Rodrigo, Gonçalo Lourinho, Tiago F. Lopes and Francisco Gírio

Fuels 2025, 6(1), 8; https://doi.org/10.3390/fuels6010008 - 23 Jan 2025

Abstract

Fossil fuels drive global warming, necessitating renewable alternatives such as biomethane (or renewable natural gas). Biomethane, primarily produced through anaerobic digestion (AD), offers a cleaner energy solution but is limited by the slow AD process. Biomass gasification followed by syngas methanation has emerged

[...] Read more.

Fossil fuels drive global warming, necessitating renewable alternatives such as biomethane (or renewable natural gas). Biomethane, primarily produced through anaerobic digestion (AD), offers a cleaner energy solution but is limited by the slow AD process. Biomass gasification followed by syngas methanation has emerged as a faster alternative. This review examines advancements in these processes over the last decade (2015–2024), focusing on techno-economic and life cycle assessment (LCA) studies. Techno-economic analyses reveal that biomethane production costs are influenced by several factors, including process complexity, feedstock type and the scale of production. Smaller gasification units tend to exhibit higher capital costs (CAPEX) per MW capacity, while feedstock choice and process efficiency play significant roles in determining overall production costs. LCA studies highlight higher impacts for gasification and methanation due to energy demands and associated emissions. However, integrating renewable hydrogen production through electrolysis, along with innovations such as sorption-enhanced gasification (SEG), can enhance overall system efficiency and reduce environmental impacts. This review critically evaluates the technical and economic challenges, along with the opportunities for optimizing biomethane production, and discusses the potential for these technologies to contribute to sustainable bioenergy solutions in the transition to a low-carbon economy.

Full article

(This article belongs to the Special Issue Biofuels and Bioenergy: New Advances and Challenges)

►▼

Show Figures

Figure 1

Open AccessArticle

Valorization of Poultry Waste Oils Recovered from Water Treatment Through the Degumming–Transesterification Process to Produce Biodiesel

by

Nayeli Gutiérrez-Casiano, José Angel Cobos-Murcia, César Antonio Ortiz-Sánchez, Solmaría Mandi Pérez-Guzmán and Eduardo Hernández-Aguilar

Fuels 2025, 6(1), 7; https://doi.org/10.3390/fuels6010007 - 15 Jan 2025

Cited by 1

Abstract

►▼

Show Figures

The growing demand for chicken meat products has increased the amount of wastewater associated with their production; their treatment has increased the generation of sludge and oils trapped in the trap process treatment. This work presents a process for the valorization of this

[...] Read more.

The growing demand for chicken meat products has increased the amount of wastewater associated with their production; their treatment has increased the generation of sludge and oils trapped in the trap process treatment. This work presents a process for the valorization of this residual oil recovered through the production of biodiesel. An oil degumming process was applied, and the quality of the treated oil was evaluated. This was transesterified with alkaline conditions and a homogeneous catalyst (KOH); a 3k experimental design was applied with two factors: the temperature at 50, 60, and 70 °C and the molar ratios of 5, 6, and 7 moles of methanol per mole of recovered chicken oil. The biodiesel quality parameters were evaluated based on the ASTM standard. The process achieved a yield of 90.2%. The biodiesel obtained met all the quality parameters; however, only the process conditions with a molar ratio of 6:1 and a temperature of 60 °C achieved a kinematic viscosity of 5.64 ± 0.15 mm2 s−1, meeting the limits of 1.9–6.0 mm2 s−1 of the ASTM regulation. The fluidity of this biodiesel in mixtures of 25, 50, and 75% v with petroleum diesel was also evaluated, and a better adjustment of the Bingham mixing rule model and rheological analysis revealed that the mixtures did not lose their Newtonian behavior. This allows for the application of this biodiesel in internal combustion engines, achieving the valorization of residual oil.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Conferences

Special Issues

Special Issue in

Fuels

Chemical Kinetics of Biofuel Combustion

Guest Editor: Elna NilssonDeadline: 15 April 2025

Special Issue in

Fuels

Sustainability Assessment of Renewable Fuels Production

Guest Editors: Stella Bezergianni, Loukia P. ChrysikouDeadline: 30 April 2025

Special Issue in

Fuels

Advances in Propulsion and Energy Systems Utilising Alternative Fuels: Fuel Injection and Combustion Systems

Guest Editors: Steven Begg, Nwabueze EmekwuruDeadline: 31 May 2025

Special Issue in

Fuels

Biofuels and Bioenergy: New Advances and Challenges

Guest Editor: Nikolaos KokkinosDeadline: 1 July 2025